Welcome to the official website of Nanyang Huaye Explosion-proof Instrument Co., Ltd!

Service Hotline:0377-61613169 | E-mail: abc@huayex.com

Improved increased safety purge system

The improved increased safety purge system is a more economical and practical motor automatic purge device designed by Huaye Explosion-proof Instrument Company based on the advantages and disadvantages of the increased safety automatic purge system and the positive pressure automatic purge control system.

Classification:

Detailed introduction

1. Overview

The improved increased safety purge system is designed by Huaye Explosion-proof Instrument Company based on the advantages and disadvantages of the increased safety automatic purge system and the positive pressure automatic purge control system. It is a more economical and practical motor automatic purge device for motors with poor shell sealing and large leakage. It mainly performs automatic purge before the motor is turned on. After the purge is completed, it automatically switches to a small flow purge to maintain a slight positive pressure in the shell (for example, a positive pressure of 1.5 to 3mba). Compared with the positive pressure purge device that has been maintained at 10mbar, the gas consumption is much smaller and more economical; compared with a single increased safety purge device (purge before starting, and cooperate with a combustible gas alarm to prevent explosion after startup), it is very practical.

This system can not only be used for internal ventilation and purge control of large motors in hazardous places, but also for internal ventilation and purge control of other electrical equipment. The system controls the purge pressure, purge flow and purge time to quickly purge the combustible gas that may exist inside the motor before starting.

For electrical equipment working in Zone 2 as specified in GB3836.14-2000, it is impossible for explosive mixtures in the form of gas, steam, mist (if they occur, they will only occur occasionally and exist for a short time) or explosive dust mixtures (which may only occur under fault conditions) to occur during normal operation. In this case, the electrical equipment pre-start purge system can be used to ensure the safe operation of the electrical equipment.

The explosion-proof performance of the purge control system complies with GB/T3836.1 "Explosive gas environment Part 1: General requirements for equipment", GB/T3836.2 "Explosive environment Part 2: Equipment protected by flameproof enclosure "d", GB/3836.3 "Electrical equipment for explosive gas environment Part 3: Equipment with increased safety "e" protection", GB/3836.4 "Electrical equipment for explosive gas environment Part 4: Equipment with intrinsic safety "ī" protection"

2. System composition

The improved increased safety purge system consists of three parts: a control unit, a wiring unit and a pressure relief unit. The outer shell is made of 316 stainless steel by brushed technology.

3. Product Features

The improved increased safety purge system is fully pneumatically controlled and all components are imported international products, which are stable, reliable and durable.

4. Model

5. Principle and Selection Guide

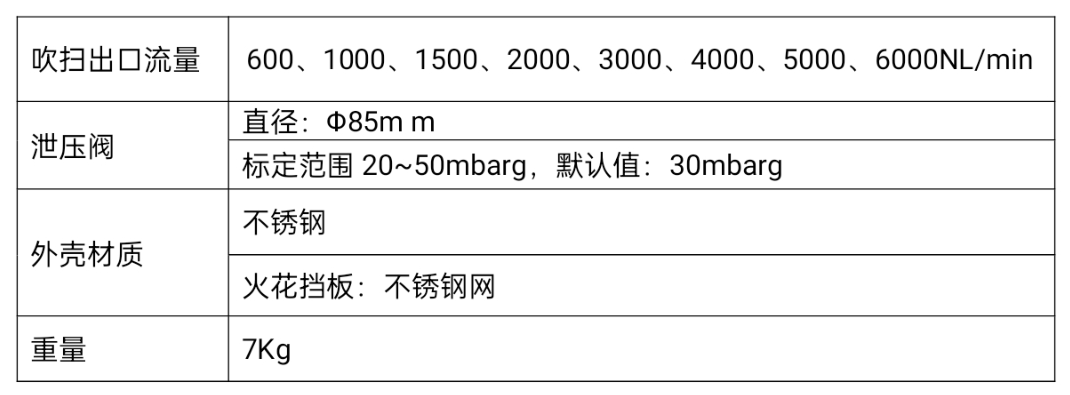

The main control unit of the improved increased safety purge system controls the supply of compressed gas and confirms the purge flow, pressure and time. The pressure relief unit serves as a safe outlet for the purge gas of the equipment and provides a signal to confirm the flow parameters of the gas in the motor cavity. The motor pre-start purge control system sets the purge flow and time according to the motor model to ensure that the gas in the shell is purged and ventilated as required for safety before each start of the motor, avoiding the unreliable factors of manual operation. When the ventilation is completed, the signal (contact switch or pneumatic signal) is linked to send the motor start permission.

When selecting the model, the user should select the purge flow according to the size of 5 times the volume of the electrical shell. Generally, the purge time takes at least 15 minutes and at most 45 minutes, and 30 minutes is usually selected. For example: the shell volume of an electrical equipment is 12000NL, and the purge flow calculation method is: 12000NLX5/30min=2000NL/min. It is more appropriate to select 2000 NL/min for the purge orifice plate flow. The definition of electrical enclosure volume in item 3.5 of GB3836.52004 is the volume of the empty enclosure without internal equipment. For rotating electrical machines, it refers to the internal net volume plus the volume occupied by the rotor.

6. Main technical parameters

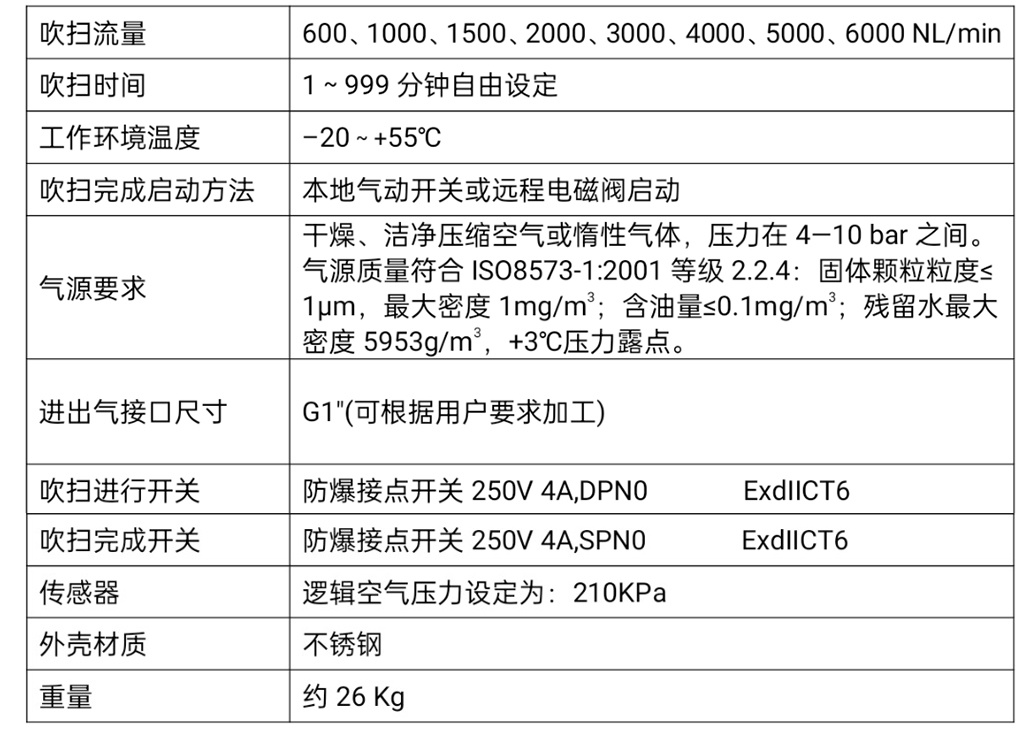

Control unit technical parameters

Wiring unit technical parameters

Outlet interface: M20×1.5, ExeⅡ cable entry device.

Pressure relief unit technical parameters

VII. Dimensions

(See Pd type dimensions)

VIII. System installation diagram

IX. Wiring Diagram

10. Installation

For the installation of the improved increased safety purge system control, refer to the system installation diagram. In front of the gas source input port of the purge device, install a G1" ball valve as the air inlet valve for easy debugging. Before connecting the gas source inlet of the purge device, open the air inlet valve to blow air to ensure that there are no impurities in the air inlet pipe, and then connect the air inlet pipe. Before turning on the gas source switch, check the outlet of the pressure relief valve to ensure that it is unobstructed.

11. Use

After the improved increased safety purge system is debugged, there are two ways to use it normally: local start or remote solenoid valve start.

1. Local start: In the main control unit, turn the local switch from the "run" position to the "reset" position until the purge light turns yellow (usually 2~5s). After the purge light turns yellow, turn the switch back to the run position.

2. Remote solenoid valve start: The main control room sends the excitation voltage of the local solenoid valve 24VDC for 2~5s.

About the two start methods, local start is mainly used for system debugging. Remote solenoid valve start is recommended for normal use. It is uniformly controlled by the main control room. The motor needs to be started and a signal (24VDC 2~5s) is sent to the purge device. The purge is completed normally, and the signal is sent back to the main control to start the motor immediately. In this way, the purge completion to the motor start is coherent and the time is controllable.

12. Maintenance

1. Check whether the air source pressure, flow rate and cleanliness meet the requirements.

2. Check the function of the purge flow sensor. There is a pressure side pilot on the pressure relief valve, which can be connected to a micromanometer or a U-type water pressure gauge. At the beginning of each purge, when the purge indicator turns yellow, the pressure value should be at least 10mbar. During daily use, regular inspections are required.

3. The main control single source built-in filter is usually maintenance-free, and needs to be inspected once a year to clean or replace the core.

4. The fire-blocking net under the pressure relief valve should be inspected regularly to ensure smooth flow.

13. System Advantages

Advantages of Huaye explosion-proof instrument automatic purge device:

1. Fast response speed

Scientific gas circuit design, the scientific combination of mode amplification and nozzle baffle technology, further expands the low-pressure response performance of the valve, and adopts the diaphragm large ring arc design, which greatly improves the sensitivity of the sensor to micro-pressure response, making the system dynamic response performance excellent, leakage compensation response rapid, and follow-up performance agile.

2. Strong stability and high reliability

Relying on the technical strength of the pneumatic laboratory, boldly innovate the gas circuit design, strive to design simple, reasonable and scientific, and adopt international products such as Bellofram, MAC, and BARTEC in the United States, so that the product has strong stability and high reliability. It can be said that the product performance indicators all catch up with or partially exceed the product.

Key words:

Improved increased safety purge system

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.