Welcome to the official website of Nanyang Huaye Explosion-proof Instrument Co., Ltd!

Service Hotline:0377-61613169 | E-mail: abc@huayex.com

BHD2-10/127-11G Mining flameproof low voltage cable junction box

Optional parameters Single junction box (without temperature sensor) With temperature sensor junction box (platinum thermal resistor Pt100) With 4-20mA temperature transmitter junction box

Classification:

Detailed introduction

1. Overview

BHD2-10/127-11G mine flameproof low-voltage cable junction box is designed and produced according to the provisions of GB/T3836.1 "Explosive gas environment Part 1: General requirements for equipment", GB/T3836.2 "Explosive environment Part 2: Equipment protected by flameproof enclosure "d", MT429-2008 "Flameproof low-voltage cable junction box for coal mines", MT381-1995 "General technical conditions for mine temperature sensors", and is manufactured into a mine flameproof product, specially used for temperature measurement in explosive mixtures (methane) and underground coal mines.

The shell is made of cast steel (or cast iron), and the surface is sprayed with anti-corrosion paint.

The explosion-proof mark is ExdbIMb.

2. Explosion-proof principle

BHD2-10/127-11G mining flameproof low-voltage cable junction box adopts explosion-proof shell, which separates the circuit part that may generate sparks and arcs from the explosive gas mixture outside the shell, so as to achieve the purpose of flameproof. The size of the flameproof joint surface conforms to the provisions of GB/T3836.2, and the cable entry device conforms to the provisions of Appendix D of GB/3836.1-2000.

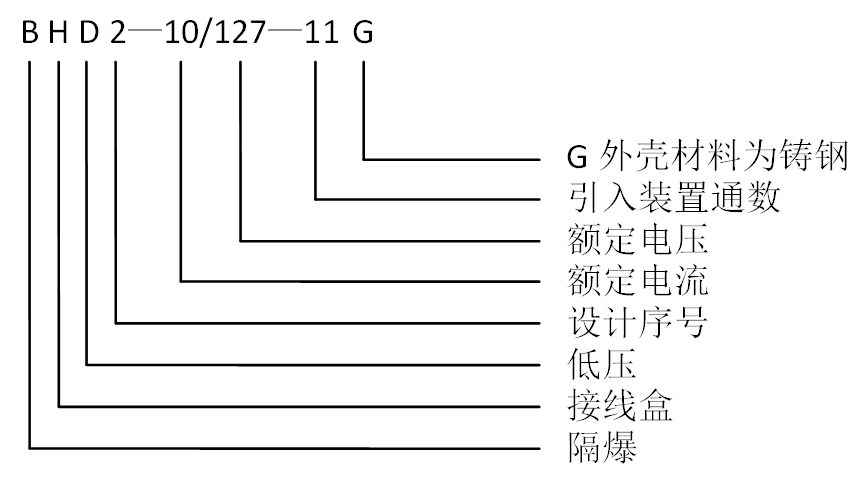

3. Model meaning

4. Technical indicators

1. Ambient temperature: -20℃~40℃;

2. Relative humidity: ≤98% (+25℃);

3. No corrosive gas that damages insulation in coal mines;

4. Operating voltage: ≤127V;

5. Atmospheric pressure: 80KPa~106KPa.

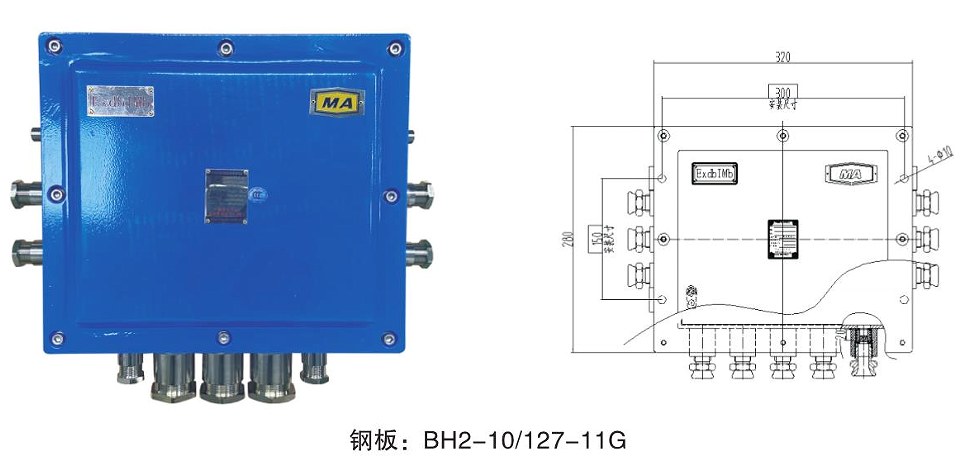

5. Appearance and installation dimensions

6. Selection Instructions

When selecting a model, the user should specify:

1. Model;

2. Whether it is equipped with a sensor or a transmitter. If equipped with a sensor, the sensor protection tube diameter and length, as well as the lead length and installation thread should be specified.

VII. Installation and wiring

1. During installation, check whether the explosion-proof mark of the brand name is consistent with the installation environment;

2. The connecting wire should be a copper shielded cable with a cross-section of not less than 0.2 square millimeters;

3. Open the junction box, use a wrench to unscrew the compression nut of the cable entry device, firmly connect the cable to the wiring bolt (or terminal) in the junction box, then cover the junction box cover and tighten the fastening screws at the four corners;

4. The grounding screw on the junction box must be reliably grounded with a grounding wire;

5. During installation, the signal transmission line should be fixed with a tie head at a distance of no more than 300mm. When the signal transmission line is too long, it can be tied in a suitable position. Do not throw it around and keep it away from heating equipment;

6. When the sealing ring in the introduction device ages and hardens, it should be replaced in time;

7. During maintenance, attention should be paid to preventing "explosion failure" (such as protecting the explosion-proof surface, paying attention to tightening and the rubber sealing ring in the introduction device);

8. The minimum outer diameter of the cable used by the user is ¢6;

9. If the "immovable" thread installation method is selected, the probe part should be installed first, and then the junction box.

Key words:

BHD2-10/127-11G

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.