Welcome to the official website of Nanyang Huaye Explosion-proof Instrument Co., Ltd!

Service Hotline:0377-61613169 | E-mail: abc@huayex.com

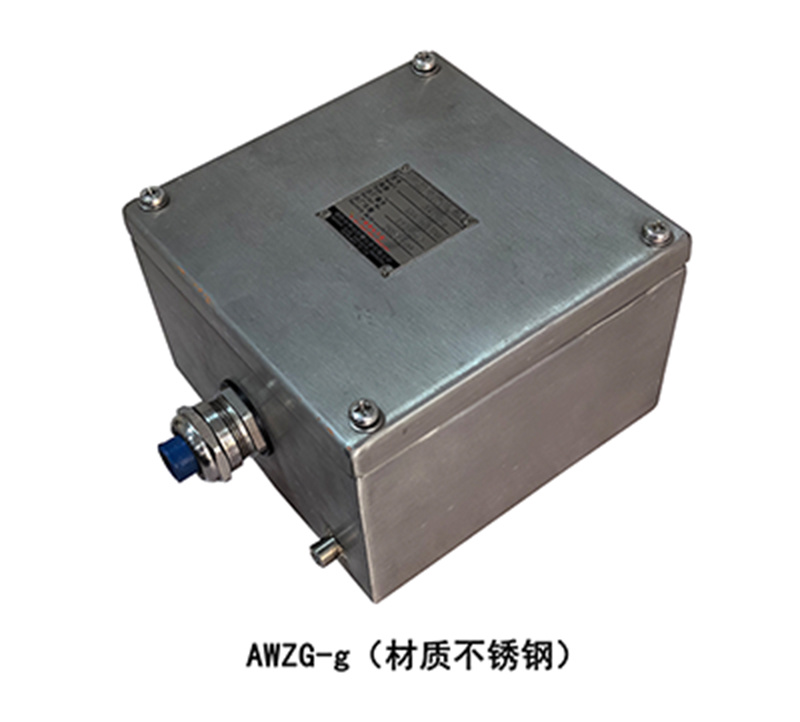

AWZG-g stainless steel increased safety explosion-proof junction box dust explosion-proof

Optional parameters AWZG-g Appearance size 160ⅹ160ⅹ110; Installation size 106ⅹ82 Customization supported

Classification:

Detailed introduction

1. Overview

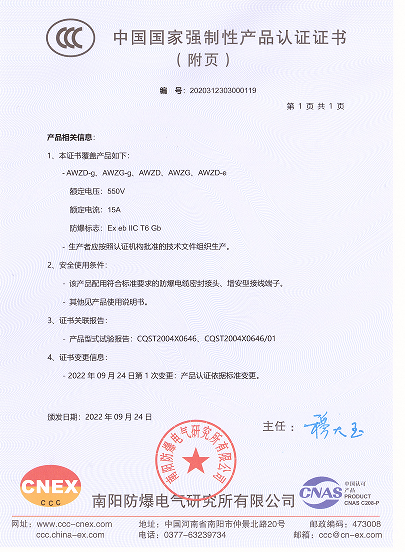

The increased safety junction box is designed and manufactured according to the provisions of GB/T3836.1 and GB/T3836.3, with explosion-proof marks ExebIICT6 Gb, ExtbIIICT80℃ Db, and protection level: IP66. It is mainly used for the connection of centralized inlet and outlet signal lines of increased safety motors, nuclear motors and wind turbines, and is also used for centralized wiring in machinery, petroleum, chemical, shipbuilding and other industries. Customization is supported.

*This product has also obtained ATEX and IEC EU certifications; EAC (CU-TR) Russian Federation Customs Union international certification.

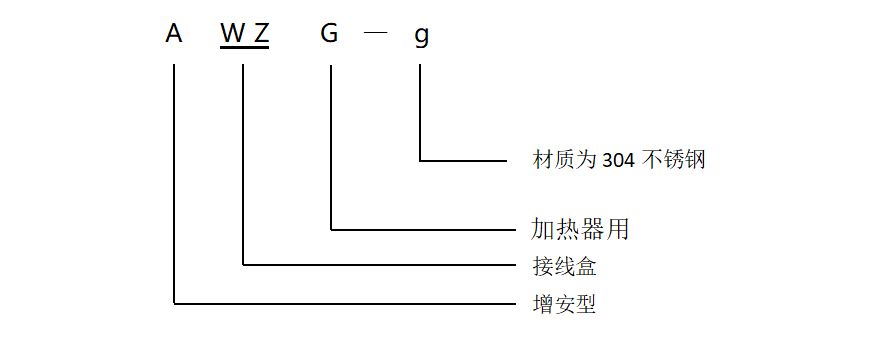

2. Model meaning

Application scope of junction box:

1. Dangerous places with explosive gas mixture: Zone 1, Zone 2\ Zone 21 of combustible dust environment

2. Explosive gas mixture: ⅡA, ⅡB, ⅡC

3. Applicable to explosive hazardous environments in motor, petroleum, machinery, chemical industry, etc., temperature group: T6

4. Altitude not exceeding 1200 meters

5. Relative humidity below 95% at 25℃

6. Working environment temperature between -20℃ and +40℃

3. Basic parameters

3.1 Explosion-proof mark: ExebIICT6 Gb, ExtbIIICT80℃ Db

3.2 Protection level: IP66

3.3 Maximum working voltage/current of each terminal: 550V/15A;

3.4 The wire diameter range of each terminal is: 0.2mm2~2.5mm2.

4. Overall dimensions: 160ⅹ160ⅹ110; Installation dimensions: 106ⅹ82

5. Explosion-proof principle

The AWZG-g explosion-proof junction box will not produce arcs, sparks or dangerous high temperatures under normal operating conditions, and further protective measures are taken in the structure to improve its safety and reliability. The cable entry device complies with the provisions of Appendix A of GB3836.1-2010.

6. Installation, wiring and precautions

6.1 When installing the junction box, check whether the explosion-proof mark on the junction box nameplate is consistent with the installation environment.

6.2 Open the junction box, use a wrench to unscrew the compression nut of the cable entry device, firmly connect the cable to the terminal (or terminal) in the junction box, then cover the junction box and tighten the screws at the four corners.

6.3 The grounding screw on the junction box must be reliably grounded with a grounding wire.

6.4 When the sealing ring in the entry device is aged and deteriorated, it should be replaced in time.

6.5 Pay attention to protecting the sealing ring or sealing strip between the upper cover and the bottom shell; if it is aged and deteriorated, it should be replaced in time.

6.6 It is strictly forbidden to open the junction box cover with power on.

6.7 During maintenance, pay attention to tightening and the rubber sealing ring in the entry device to avoid scratches or abrasions.

6.8 After the entry (exit) line connection is completed during installation, the upper cover should be installed tightly and the installation screws should be firm.

Key words:

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.